Leather & Leather Alternatives

Traditional leather is made from animals, through a largely unregulated and often cruel process, while most alternatives (often marketed as ‘vegan’), are usually made entirely from synthetic materials. Discover how we approach leather and its alternatives at PANGAIA, and the problem-solving solutions we’re exploring.

The problem with animal leather.

Leather is most commonly made from animal hides from bovine (cow), ovine (sheep) porcine (pig) or caprine (goat), which is processed into a finished product through tanning. The main issue with sourcing animal leather is the slaughter— a largely unregulated, cruel industry with intensive chemical processing required. Currently, most alternatives available on the market are fossil fuel-based (a non-renewable resource) and can’t be recycled.

The problem with synthetic alternatives.

Two of the most common alternatives to animal leather are PVC (polyvinyl chloride) and PU (polyurethane).

PVC

- Is derived from finite fossil fuel sources

- Is chemically-intensive to manufacture and uses chemicals found on Restricted Substances Lists (RSLs)

- Releases dioxins (toxic chemical compounds) into the environment during production

- Incorporates phthalate plasticizers (hormonal disruptors) which are dangerous to humans and ecosystems

- Cannot be recycled and releases toxic chemicals in landfill

PU

- Is a synthetic polymer made from petroleum-based chemicals (its raw material is crude oil)

- Uses toxic chemicals, finite natural resources, harmful solvents and high amounts of energy in production

- Releases toxic compounds when waste is burned

- Does not biodegrade at the end of its life

Though PU is safer for humans than PVC, it’s still dependent on petrochemical raw materials. In order to make PU workable for a vegan alternative it must be turned into a liquid using harsh solvents. These solvents are usually high in volatile organic compounds (VOCs), which are harmful to humans and the environment. But, recent advances in chemistry have developed a less toxic process known as water-based polyurethane or polyurethane dispersion (PUD). This involves modifiers and other agents in addition to water, which means PUD is a less toxic and harmful process, although we are aware PUD still relies on petrochemical raw materials and does not biodegrade at the end of its life.

Our perspective.

We will never source animal-derived skins for PANGAIA products. We are committed to discovering and developing innovative alternatives that are recyclable or harmlessly biodegradable in the natural environment.

Our stance on synthetics informs our approach to sourcing alternative material options. As it stands, no single alternative to animal leather meets all of our sustainability requirements, but we are continually searching for and sourcing new innovations that are high quality and meet the needs of our products.

Most of the current plant-derived versions are a combination of materials, made by combining biomass waste with polyurethane dispersion (PUD) to improve the physical properties of the material. While the addition of PUD improves the properties of the final material, it stops the material from biodegrading fully, rendering the material more complicated to be recycled.

Our questions when sourcing alternatives.

- What is the material source?

- Is it recyclable?

- Is it biodegradable?

- Does it have enhanced degradation properties?

- Does the manufacture of the material involve a chemically intensive process?

Alternatives we work with.

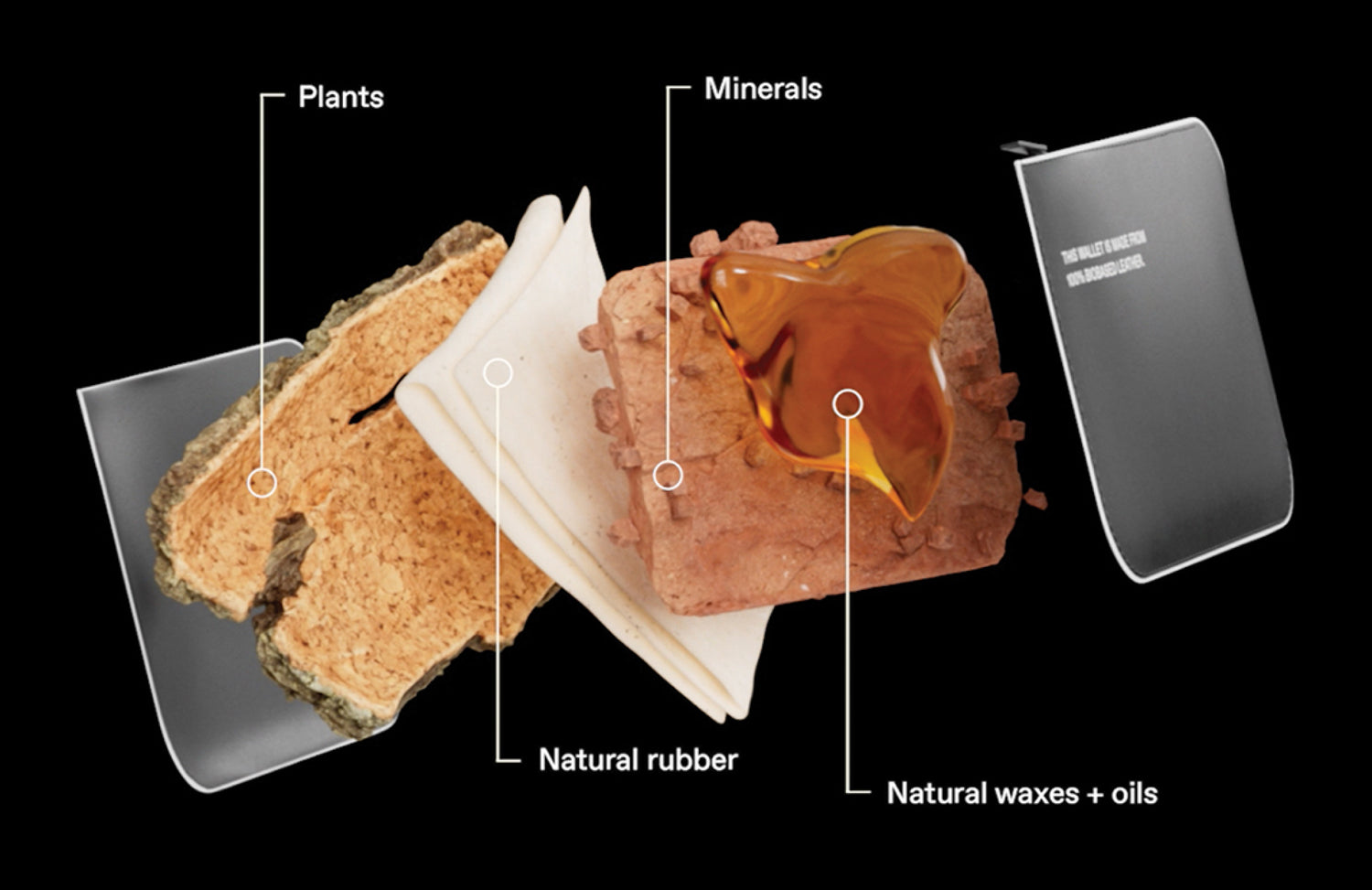

Natural Fiber Welding—MIRUM®

MIRUM® is a 100% biobased, composite material with all raw inputs sourced from virgin or recycled plant matter (agricultural waste). Natural inputs, such as rubber and cork, are sourced from well-managed forests, with FSC certification. This alternative is completely petrochemical-free and eliminates the dependency on fossil fuels.

Additionally, this material has the capability to be 100% recyclable and 100% circular, when disassembled and entered into the correct waste stream or as a raw material. While MIRUM® as a material itself is fully recyclable, at PANGAIA we are still working on our end of life services for our products. We are currently exploring exciting opportunities that provide circular solutions for our products, such as take back, sorting and recycling.

Vegea—grape material

Vegea is an innovative material characterized by its high content of vegetable, renewable and recyclable raw materials: grape skins from winemaking, and vegetable oils and natural fibers from agriculture. Vegea’s grape material utilizes and repurposes waste materials, extending the utility of the grapes and making the winemaking process more circular.

The base material is organic cotton, and is coated with the most environmentally-responsible form of polyurethane on the market. Unfortunately, the material is not yet biodegradable and is difficult to recycle. With that in mind, PANGAIA has selected specific end-use products for this material, specifically in a product that is low-wash and long-lasting, like footwear.